Forging our story

since 1909.

Our journey in the metallurgy of non-ferrous metals began back in 1909. Over a century of dedication, innovation, and craftsmanship has shaped Masperotech into what it is today—a company deeply rooted in tradition, yet constantly looking to the future.

From these solid foundations, driven by a relentless pursuit of excellence, we’ve built extensive expertise in the hot forging of Aluminium, Copper, and Titanium alloys. Our know-how has grown through generations, guided by the principle that defines our heritage:

“Create and produce the best possible products.”

This timeless rule continues to inspire every aspect of our work, especially in the development of cutting-edge production processes.

Thanks to the continuous integration of advanced technologies, we’ve transformed this culture of quality into an industrial reality—scalable, reliable, and future-oriented.

Today, Masperotech stands as a European leader in the hot forging of non-ferrous metals. Our mission is to generate value for our stakeholders, exceed customer expectations, empower our people, and contribute responsibly to the community, the environment, and future generations.

our mission

We want to be a European leader in the field of hot forging of non-ferrous metals, for the production of complex and technologically advanced structural components with sizes up to a few hundred. We aim to satisfy our customers and generate profits for our shareholders, developing the capacity and skills of all our employees while respecting the environment and future generations.

our

growth

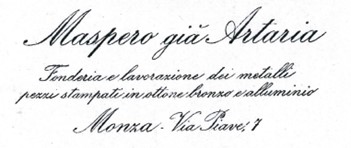

Purchased by Fermo Maspero from the Fonderia Artaria, the company initially engaged in sand and shell casting of nonferrous metals.

A new headquarters is built at Via Piave 7, in Monza, with a shed of just over 400sqm.

Fonderia Maspero casts handles for Milan's Central Station and is run by the founder with his daughter Tina, one of the first women to graduate with a diploma in accountancy in 1925 from Milan's Carlo Cattaneo Institute.

To diversify and qualify the offerings, the first screw press (balance) for hot stamping and a few years later a new press for die casting are brought into the company.

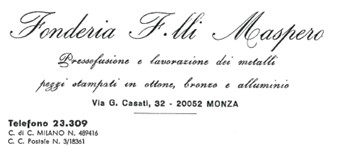

A new area at Via Casati in Monza is purchased and the business is relocated with the entire Maspero family.

A new 1000-ton hydraulic press is acquired.

As the third generation joined the company, the sand-casting business was permanently abandoned to focus on hot stamping of nonferrous metals.

As a result of the great growth in sales, the production area is expanded through the purchase of the adjacent area of the Philips cathode factory and the construction of a new 2,000-square-meter building.

The area of Via Ercolano in Monza (current headquarters), equal to about 35 thousand square meters, is acquired.

Considered today one of the leaders in Europe for mechanical processing of non-ferrous metals, mainly Aluminum and Copper alloys.

The new press has a base of 2700 x 1700mm. It weighs an impressive 750,000kg and is just over 11 meters high. Thus begins a new adventure for all of us: new challenges, new areas and new projects.

Another new 7,000-ton hydraulic press is installed, with a machine table size of 2300x1700mm, a stroke of 1200mm and a height of 9m. Investments in technology and electromechanics are necessary in our field to provide customers with the best products. This is why CMO Group decided to purchase a new press to make new products, which can reach 2.30m in length.

our logo

through the years

Curiosity, passion, culture, determination, a propensity for reasoned risk-taking and attention to technological development.

Without this background, an industrial history spanning more than a hundred years cannot be built.

We have navigated the sea of nonferrous metal metallurgy through the years, always applying two fundamental principles:

- Building partnership relationships with our Customers.

- What we know today is the basis for what we need to know tomorrow.

1930

1956

1980

2009

2014

2019

2023

1930

1956

1980

2009

2014

2019

2023