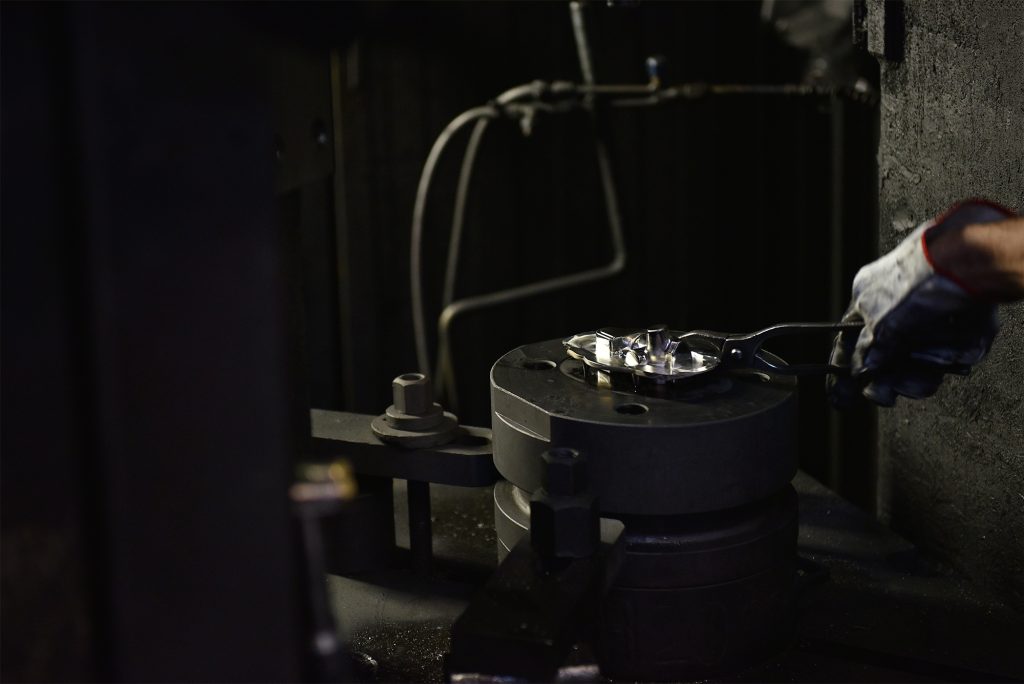

Hot stamping is Masperotech’s main production activity.

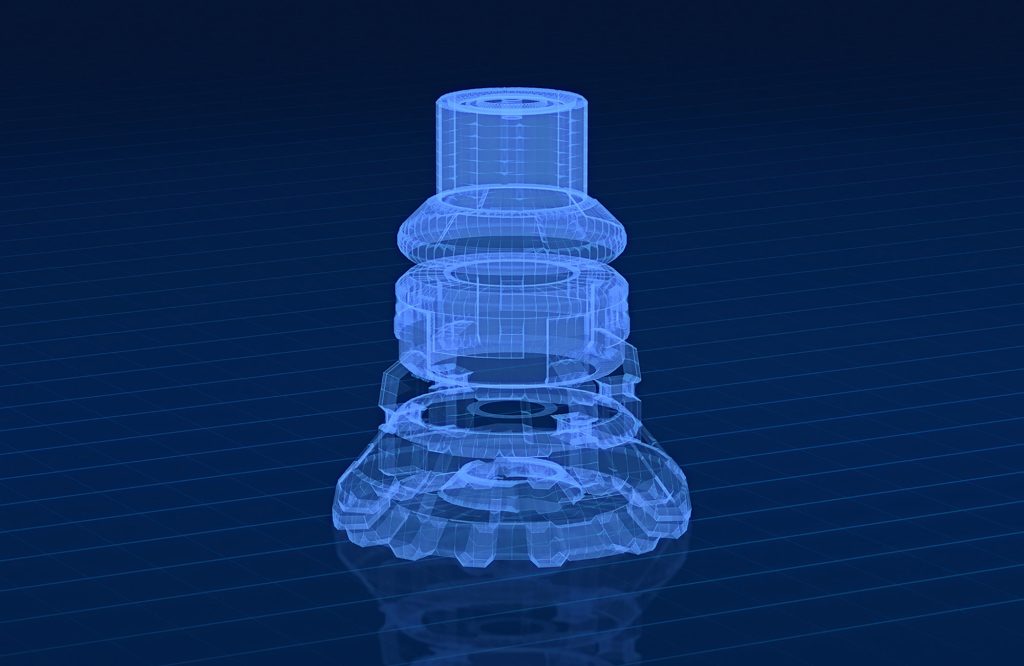

It is a metal remolding process implemented by means of a compressive force applied to a preheated billet, which generates sufficient deformation within the mold to achieve the desired geometric shape.

We can forge all non-ferrous metals, Aluminum, Copper, Brass, Titanium, CuNi, Monel, AluBronze, making parts of varying weights and sizes, thanks to our 12,000-ton press:

From just a few grams up to 400 kg

with a maximum size of about 3 meters in length

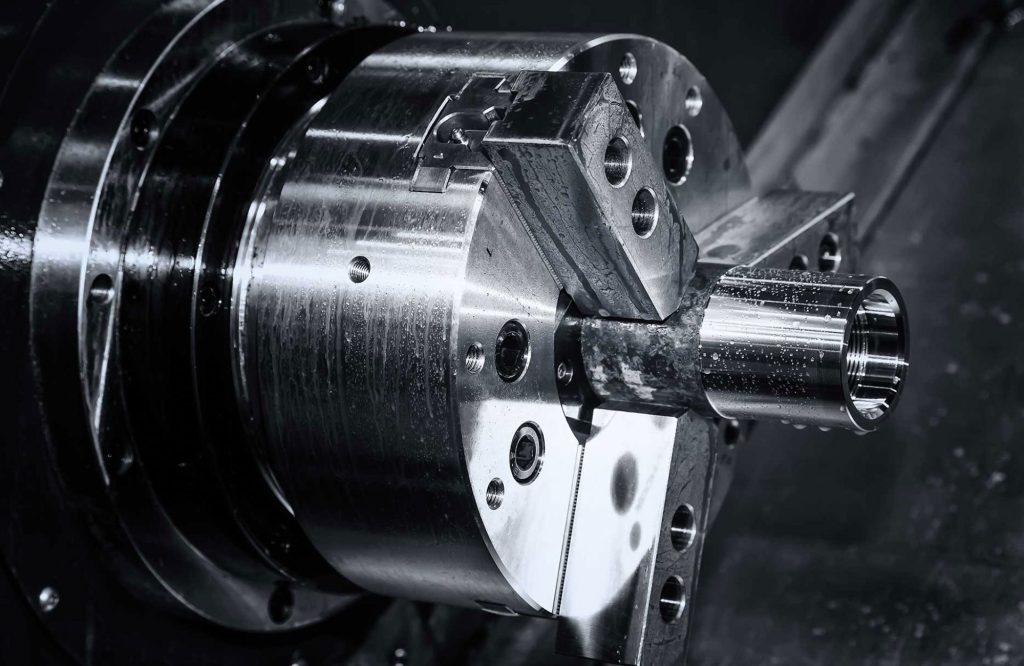

The production of hot forged parts offers specific advantages when it comes to mechanical properties.

In particular, forging metals can increase the product’s strength as well as being able to modify the metal’s inter-granular structure due to the metal flowing during reshaping, and can be used to create a specific granular structure to increase the strength of the forged items.

For these reasons, hot forging offers significant advantages in terms of mechanical properties over those made by other technologies, such as casting or machining

MasperoTech S.r.l. – VAT / C.F.: 04458170968 – Capital i.v: 880.000,00 Euro – REA n. MB 1750028 (nr. iscr. CCIA Monza e Brianza)